Quality

QualityQUALITY POLICY

Arizzi Fonderie, particularly over the last few years, has deepened its commitment ensuring the highest standards of quality.

The continuous search for improved process and product quality has enabled Arizzi Fonderie to become the supplier of important international groups who are leaders in quality and technological innovation in their respective sectors; this is the best possible reference that we could have.

The results obtained are the fruit of a quality policy that Arizzi Fonderie has had in place for many years and rests on solid foundations:

- LEARNLEARN

- INNOVATEINNOVATE

- PROGRESSPROGRESS

|

Training, promoting the growth of and searching for human resources because we know that the quality of our product is the result of the work of all the people in the company. |

|

Continuous plant improvement (sand plant, new shotblasting machines, new press-pouring furnace, plant for cored wire spheroidizing). |

|

Satisfying old and new customers and supply sectors characterised by high standards of quality and excellence. |

RAW MATERIALS QUALITY CONTROL

Choosing selected raw materials and the correct alchemy of the elements.

The deliberate decision to acquire the best raw materials supported by the best technologies for preparing and controlling molten metal in order to obtain the best product ever and at all times.

- ANALYTICAL CONTROLANALYTICAL CONTROL

- THERMAL ANALYSISTHERMAL ANALYSIS

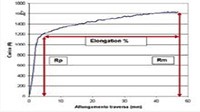

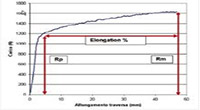

- MECHANICAL TESTSMECHANICAL TESTS

|

A close control plan that continuously monitors the analytical quality of the metal through the cast product in the moulds. |

|

The most modern and effective production process evaluation approach for identifying the graphitic behaviour and consequent metallurgical defects. |

|

Continuous mechanical traction, % elongation and impacts tests conducted by accredited bodies and laboratories. |

CHECKING CASTS FOR DAMAGE

So that you also know about what you don’t see.

The result of a complex process can hide defects that are invisible to the naked eye. Validation of the processes plays a fundamental role in guaranteeing the soundness and conformity of the cast object and in order to obtain validation, destructive and non destructive tests must be conducted.

- US TESTUS TEST

- DESTRUCTIVE TESTSDESTRUCTIVE TESTS

- MAGNETIC AND RADIOSCOPIC TESTSMAGNETIC AND RADIOSCOPIC TESTS

|

Methodical use of ultrasound to detect defects near critical areas. |

|

Destructive sectioning of one or more items that are representative of the batch under examination in addition to the ultrasound test. |

|

Integrity certification by radioscopy and/or magnetic controls to identify possible hidden tensions and cracks. |

CHECKING MOULDS

Looks are important too.

The work that goes into obtaining excellent metal must not be spoilt by a sand mould that does not have the correct characteristics. Above all, the integrity of the mould gives the product a uniform shape that is free of irregularities and is easy on the eye – as it should be.

- CHECKING CORESCHECKING CORES

- SAND CHECKSAND CHECK

- MOULD HARDNESSMOULD HARDNESS

|

Working with leading partners helps maintain high quality standards; the control system introduced ensures conformity upon arrival, storage and during conservation of the cores. |

|

In order to obtain a suitable mixture of green sand, the best sands and the most efficient and ecological additives are chosen; the quality of these materials is systematically checked upon arrival.

The mechanical properties of the sand produced are systematically checked at each preparation cycle by means of an automatic Hartley Control ® device and the dispatch of samples to accredited laboratories. |

|

The calibration of moulding is checked and tested by systematic checking the mould hardness. |

CHECKING CASTING PROPERTIES

Demonstrating the conformity of your project is our greatest satisfaction.

Blank precision has never reached such a high level. And it can only be demonstrated by measuring it. The exact measurement enables us to declare the degree of structural, dimensional and geometrical conformity of the item.

- INSPECTING GEOMETRY INSPECTING GEOMETRY

- HBW CHECKING HBW CHECKING

- CHECKING DIMENSIONSCHECKING DIMENSIONS

|

Hardness is a very important parameter but is affected by the geometry of the item and the quality of the material. We use fixed and/or portable hardness meters to measure hardness. |

|

Traditional dimensional checks are offered to check linear dimensions. |

|

The best technological solution available with which to realistically scan the surfaces of the object and compare the result with the native 3D drawing. The result enables the geometrical-dimensional conformity of the object to be observed. |

SYSTEM QUALITY

Demonstrating the conformity of your project is our greatest satisfaction.

Blank precision has never reached such a high level. And it can only be demonstrated by measuring it. The exact measurement enables us to declare the degree of structural, dimensional and geometrical conformity of the item.

- TRACEABILITYTRACEABILITY

- ISSUING CERTIFICATESISSUING CERTIFICATES

- ISO9001 CERTIFICATIONISO9001 CERTIFICATION

|

Each phase of the process is stored in the computer system and is managed using batch BARCODES to ensure that the batches can be traced and retraced. |

|

In conformity to standard UNI EN 10204, we publish the certificate that is most suitable for the contract in order to certify its quality. |

| Since 1998 the UNI EN ISO 9001 system has been adopted and followed that is issued by the Det Norske Veritas body. |