Engineering

EngineeringEngineering

Let’s design together!

If you have an apple and I have an apple and we exchange these apples then you and I will still each have one apple. But if you have an idea and I have an idea and we exchange these ideas, then each of us will have two ideas.

(George Bernard Shaw)

Starting with a drawing, our technical staff automatically make the modifications required for product industrialisation and engineers the mould required to make the product.

Arizzi Fonderie designs and engineers the mould for you that is the most suitable for producing casts by designing the ideal configuration using the most suitable materials, from wood to metal, and the highest quality resin.

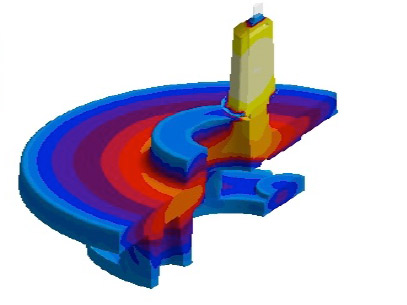

- SIMULATIONSIMULATION

- REVERSE-ENGINNERINGREVERSE-ENGINNERING

- CO-DESIGNCO-DESIGN

|

We work with you right from the design phases to find the most effective solution. We subject your project to digital simulation to identify weak zones during the solidification of the item. |

|

If the drawings are not available, Arizzi technical staff can find them for you with reverse engineering, starting from a sample. |

|

A common objective! Obtaining a quality product is also a result of sharing information. We offer you all our experience for making your product compatible with casting processes. |